Introduction

Across Canada and globally, the shift toward sustainable recycling technologies is more than just a trend, it’s a necessity. As landfills overflow and environmental regulations tighten, clean-tech OEMs are turning to advanced waste-to-energy solutions like pyrolysis and gasification systems. These systems convert waste into valuable resources such as syngas, oil, and char, while minimizing emissions and maximizing energy recovery.

But the question many industry leaders ask is: “How are pyrolysis systems manufactured?”

The answer lies in a highly specialized, end-to-end fabrication process that requires precision engineering, durable materials, and turnkey execution. At Waycon Manufacturing, we pride ourselves on delivering environmental recycling equipment that is built to last. Every step from initial design and custom CNC machining to conveyor builds, sandblast finishes, and compliance testing is completed under one roof. This ensures efficiency, quality control, and seamless delivery for OEM partners.

In this blog, we’ll walk through the complete journey of how pyrolysis and gasification systems are fabricated at Waycon, showing how our expertise in waste-to-energy fabrication helps OEMs bring clean-tech projects to life.

Understanding the Manufacturing of Pyrolysis Systems

When looking at pyrolysis and gasification systems, it’s important to recognize that these are not off-the-shelf products. Each unit must be engineered to handle specific waste streams whether municipal solid waste, industrial residues, or biomass.

At Waycon, the fabrication process begins with:

- Custom design & engineering – tailored for capacity, feedstock type, and emission standards.

- Fabrication & CNC machining – ensuring reactor vessels, piping, and frames are built with exact tolerances.

- Assembly & conveyor integration – connecting all mechanical and electrical components into a functional unit.

- Quality assurance testing – guaranteeing performance and safety before shipment.

Unlike generic fabrication shops, Waycon takes a turnkey approach. By handling design, fabrication, finishing, and assembly in-house, we ensure that each pyrolysis system leaves our facility ready for integration at the OEM’s site.

Our proven track record in environmental recycling equipment has made Waycon a trusted partner for clean-tech OEMs across Canada. If you’re exploring solutions, review our waste-to-energy manufacturing expertise to see how we can support your next project.

Step 1: Custom Engineering & Design

The foundation of every successful pyrolysis or gasification system lies in its design. Waycon engineers collaborate directly with OEM clients to ensure each unit aligns with project goals and operational needs.

- 3D CAD modeling allows precise visualization of layouts.

- Finite element analysis (FEA) validates structural resilience under high-temperature conditions.

- Safety protocols are integrated early to meet Canadian and international standards.

For OEMs, this stage is critical. It ensures that every bolt, weld, and conveyor alignment is mapped out before fabrication begins. By investing time in robust design, Waycon minimizes project risk and reduces costly revisions during later stages.

To explore how our custom fabrication solutions start at the design stage, visit our engineering capabilities.

Step 2: Fabrication & CNC Machining

Once the design is finalized, fabrication begins. This is where ideas transform into durable components. Waycon’s advanced shop floor is equipped with custom CNC machining capabilities, heavy fabrication tools, and specialized welding stations.

Key steps include:

- Material preparation – high-grade steels are selected for strength and corrosion resistance.

- CNC machining – critical for reactor shells, piping connections, and precision-cut frames.

- Heavy welding – ensures joints can withstand high pressure and thermal cycling.

- Sandblast finishing – adds durability and prepares surfaces for protective coatings.

Unlike outsourcing, Waycon keeps fabrication in-house. This allows for real-time quality checks and faster turnaround times for OEMs. Each component undergoes strict inspection to guarantee tolerances are met.

By integrating waste-to-energy fabrication with CNC precision, Waycon ensures every pyrolysis system is robust enough for industrial duty. Learn more about our custom manufacturing capabilities.

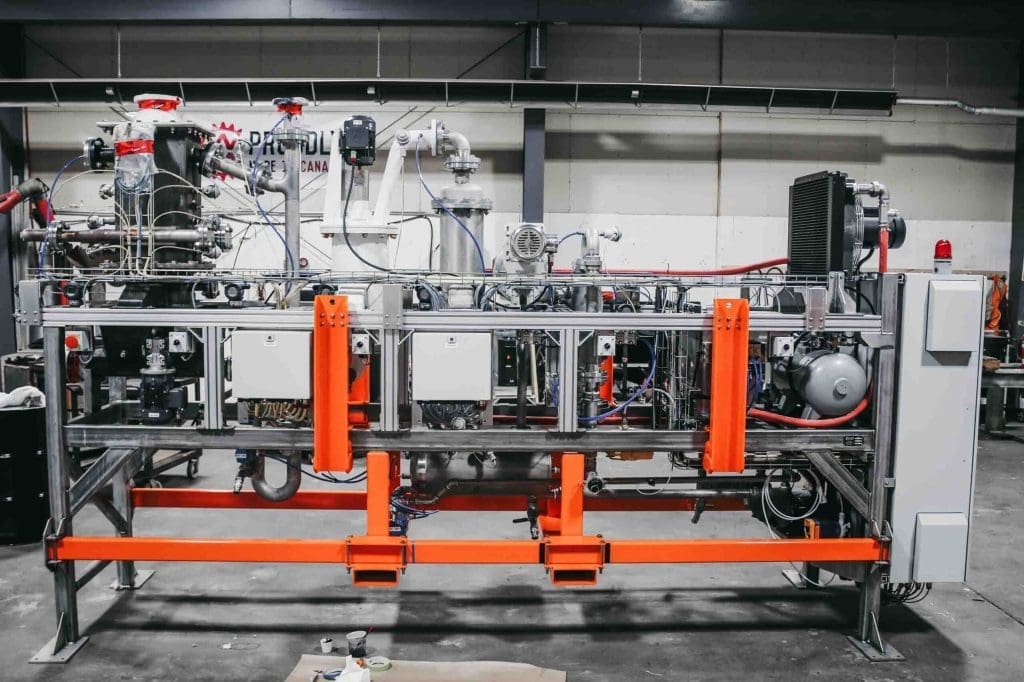

Step 3: Assembly, Conveyors & Testing

After fabrication, the individual components come together during assembly. Pyrolysis and gasification systems require seamless integration of mechanical, thermal, and emission-control elements.

Waycon’s turnkey assembly process includes:

- Installing custom conveyor builds for feedstock handling.

- Aligning reactors, hoppers, and filtration systems.

- Connecting piping, control panels, and mechanical linkages.

This stage ensures the system operates as one unified waste-to-energy solution. Before shipment, Waycon subjects each unit to operational testing, verifying throughput, heat stability, and emissions control.

OEMs benefit from receiving a fully integrated unit that requires minimal adjustment on-site, saving both time and costs. For insight into how we execute these builds, review our project process.

Step 4: QA, Safety & Compliance Testing

Before leaving our facility, every pyrolysis system undergoes comprehensive quality assurance. This includes:

- Pressure testing for reactor and piping systems.

- Thermal validation to confirm stable high-temperature operation.

- Emission testing to verify environmental compliance.

OEMs rely on Waycon’s testing protocols to ensure their systems meet both Canadian standards and international guidelines. By validating performance in-house, Waycon eliminates the guesswork during installation.

Why Choose Waycon for Waste-to-Energy Fabrication

OEMs face many choices when it comes to fabrication partners. What sets Waycon apart is our end-to-end capability. From engineering and CNC machining to assembly and final testing, every stage is handled under one roof.

Key advantages include:

- Turnkey delivery – OEMs receive fully integrated, install-ready systems.

- Custom solutions – every project is built to specific environmental goals.

- Quality control – rigorous inspection ensures performance and compliance.

- Canadian expertise – trusted across North America for clean-tech builds.

Whether you’re developing a new waste-to-energy facility or upgrading existing infrastructure, Waycon delivers reliable, innovative solutions. To discuss your project, contact us today.

Conclusion

So, how are pyrolysis systems manufactured? At Waycon, the answer is simple: with precision, expertise, and a turnkey approach that puts OEMs first.

- Engineering & design ensure tailored solutions.

- Fabrication & CNC machining provide strength and accuracy.

- Assembly & conveyors integrate the full system.

- Testing & finishing guarantee long-term performance.

By combining all these steps under one roof, Waycon Manufacturing makes waste-to-energy systems more reliable and more efficient for clean-tech OEMs.If you’re ready to explore a pyrolysis or gasification fabrication project, start with the Waycon home page or reach out directly through the contact page. Together, we can build systems that advance sustainable energy while reducing environmental impact.