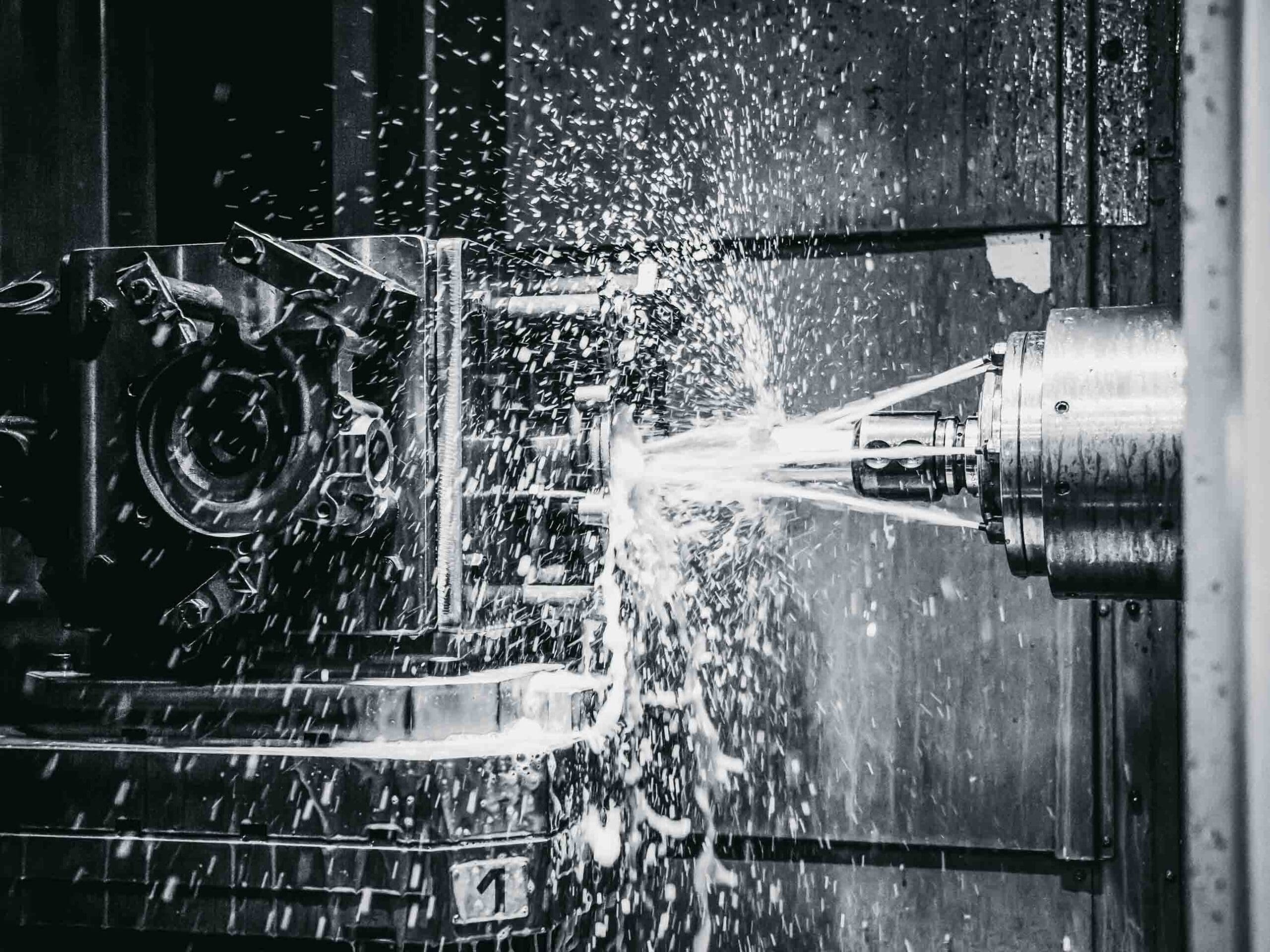

With our extensive machining capabilities, Waycon can handle high-value, low-volume production machining and prototype work, as well as various machining processes for small to large parts. Our agility makes us unique, as we minimize setup time and maintain a quick turnaround for complex projects without compromising quality.

We have extensive experience in Computer Numerical Control (CNC) machining, allowing us to precisely produce various parts from a range of raw materials. While this service is a single-process operation focused exclusively on machining, we also offer customization with additional services such as engineering support, prototyping, full fabrication, finishing, assembly, and testing.