In the world of manufacturing and industrial design, precision is everything. When a project involves complex geometries, unique specifications, or innovative concepts, off-the-shelf components simply will not do. Standardized parts can force engineers to compromise their vision, leading to designs that are less efficient, less effective, and less competitive. This is where the power of custom fabrication becomes an invaluable asset for any forward-thinking business.

Custom fabrication is the process of creating specialized metal parts, components, and structures from raw materials, based on a client’s exact designs and requirements. It moves beyond the limitations of mass production, offering a tailored solution that ensures every piece fits and functions perfectly within a larger assembly. For businesses that rely on innovation and quality, choosing a skilled fabrication partner is a strategic decision that impacts everything from product performance to the bottom line.

The Limitations of Off-the-Shelf Solutions

Standard parts are designed for general applications. While they can be cost-effective for simple, high-volume projects, they present significant challenges when dealing with complex or specialized designs. Engineers may be forced to design around the available components, which can add unnecessary complexity, weight, or weak points to the final product. This compromise can hinder innovation and result in a product that doesn’t fully meet its intended purpose.

Furthermore, relying on a patchwork of standard parts can lead to tolerance stacking—where small, acceptable deviations in each part accumulate into a significant error in the final assembly. This can cause functionality issues, premature wear, and a higher failure rate. In industries where reliability and precision are paramount, such as aerospace, agriculture, or specialized machinery, these compromises are simply not an option. Custom fabrication eliminates these issues by creating components designed to work together seamlessly.

Unparalleled Precision and Quality Control

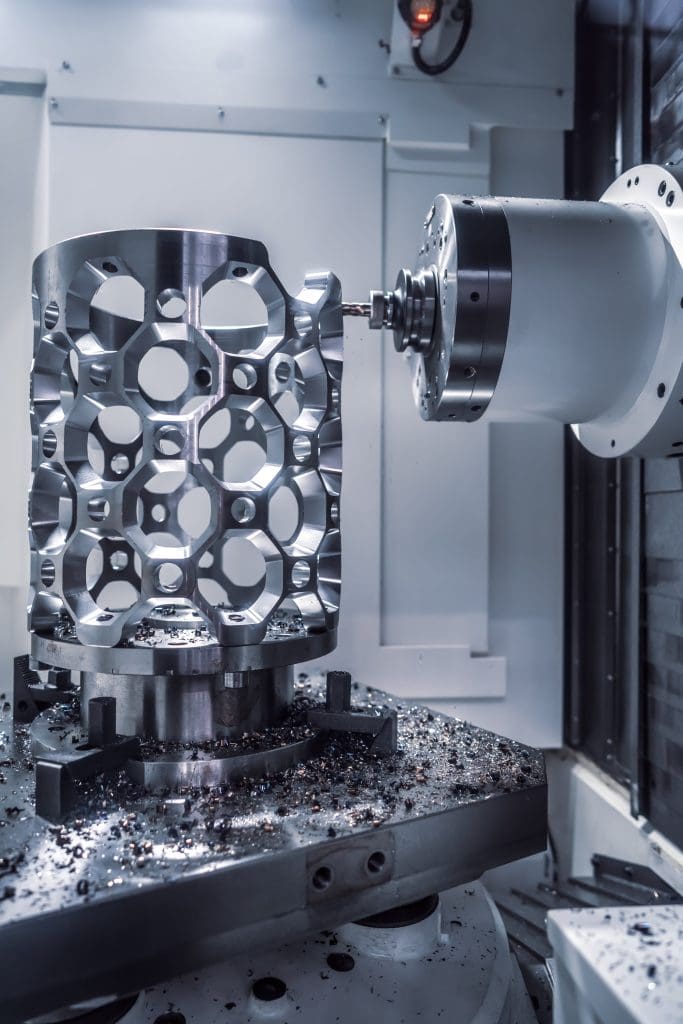

The single greatest advantage of custom fabrication is the ability to achieve unparalleled precision. When you partner with a specialized fabricator, you are working with a team that can translate your detailed CAD drawings into a physical product with exacting accuracy. Using advanced equipment like CNC (Computer Numerical Control) machines, laser cutters, and precision welders, skilled technicians can create components that meet even the most stringent tolerances.

This level of control ensures that every part is manufactured exactly as designed. It eliminates the guesswork and variability associated with off-the-shelf parts, guaranteeing a perfect fit and optimal performance. At Waycon Manufacturing, our quality control process is integrated into every step of the fabrication journey. From the initial material selection to the final inspection, we ensure that every piece leaving our facility meets the highest standards of quality and accuracy.

Ultimate Design Flexibility and Innovation

Custom fabrication empowers engineers and designers to push the boundaries of what is possible. Instead of being constrained by a catalog of pre-made parts, they are free to create the most efficient and effective design for the task at hand. This flexibility is crucial for innovation. It allows for the creation of unique, proprietary designs that can give a business a significant competitive advantage.

Whether it’s developing a lighter, stronger structural component, designing a specialized piece of equipment for a unique industrial process, or creating a complex architectural feature, custom fabrication provides the means to bring ambitious ideas to life. This process is inherently collaborative. A good fabrication partner will work closely with your design team, offering feedback on material selection and manufacturability to help optimize the design for both performance and cost-effectiveness.

Cost-Effectiveness for Complex Projects

There is a common misconception that custom work is always more expensive than using standard parts. While the upfront cost per piece might be higher, custom fabrication is often more cost-effective in the long run, especially for complex or low-to-medium volume projects. By designing parts specifically for the application, you can reduce the total number of components required, minimize assembly time, and eliminate the need for costly modifications on the shop floor.

Furthermore, custom parts can be designed for maximum material efficiency, reducing waste and lowering material costs. The durability and reliability of precisely fabricated components also lead to lower maintenance and replacement costs over the product’s lifespan. When you factor in the enhanced performance and reduced long-term expenses, custom fabrication delivers superior value and a higher return on investment.

Prototyping and Iterative Development

The journey from concept to final product often involves multiple stages of testing and refinement. Custom fabrication is essential to this iterative development process. A skilled fabricator can quickly produce prototypes that allow your team to test the form, fit, and function of a new design in a real-world setting. This is a critical step for identifying potential flaws and making necessary adjustments before committing to a full production run.

This ability to rapidly prototype and iterate allows for a more agile and responsive design process. It reduces the risk of costly errors and ensures that the final product is fully optimized and ready for the market. Working with a local fabrication shop in Kelowna, like Waycon, streamlines this process even further, allowing for faster turnaround times and closer collaboration between your engineers and our fabrication experts.

Choosing the right partner for your custom fabrication needs is as important as the design itself. You need a team with the experience, equipment, and commitment to quality to execute your vision flawlessly. At Waycon Manufacturing, we have built our reputation on delivering exceptional custom metalwork for a wide range of industries.

Our state-of-the-art facility is equipped with the latest technology, and our team of certified welders, machinists, and fabricators are experts in their craft. We pride ourselves on our problem-solving abilities and our collaborative approach. We work as an extension of your team, providing the expertise and support you need to turn complex designs into high-quality, reliable products. Our comprehensive custom metal fabrication services are designed to handle projects of any scale and complexity.

Don’t let standard components limit your potential. Embrace the precision, flexibility, and quality of custom fabrication to create products that stand out in the market.

Ready to discuss your next project? Reach out today and let the experts at Waycon Manufacturing show you how we can bring your complex designs to life.

How Partnering with Canadian Manufacturing Companies Benefits Your Business

In a globalized market, businesses have more choices than ever when it comes to sourcing production and manufacturing. The decision of where to build your products is a critical one, with long-term implications for quality, logistics, and your bottom line. While overseas manufacturing can sometimes seem appealing on the surface, many innovative companies are discovering the powerful advantages of keeping their production closer to home. Partnering with Canadian manufacturing companies offers a unique combination of quality, reliability, and strategic benefits that can give your business a significant competitive edge.

Choosing a domestic manufacturing partner is more than just a patriotic decision; it’s a smart business strategy. It’s about strengthening your supply chain, ensuring unparalleled quality, and fostering collaboration that leads to better products. This guide will explore the key benefits of working with a Canadian manufacturer and show why local expertise is one of the most valuable assets your business can have.

Unwavering Commitment to Quality and Standards

One of the most compelling reasons to choose Canadian manufacturing is the unwavering commitment to high-quality standards. Canadian manufacturers operate under some of the most stringent regulations in the world, covering everything from materials and labour practices to safety and environmental impact. This rigorous regulatory framework ensures that products made in Canada are built to last, providing a level of quality and durability that is recognized globally.

When you partner with a Canadian company, you can be confident that you are getting a product made with superior materials and expert craftsmanship. There are no shortcuts when it comes to quality. This commitment translates directly into the reliability of your own products, reducing the risk of defects, recalls, and warranty claims. It builds trust with your customers and enhances your brand’s reputation for excellence, which is an invaluable long-term asset.

A More Resilient and Reliable Supply Chain

The last few years have highlighted the fragility of global supply chains. Delays in shipping, port congestion, and geopolitical instability can bring overseas production to a grinding halt, leaving businesses with empty shelves and missed deadlines. By partnering with a Canadian manufacturing company, you insulate your business from much of this volatility. A domestic supply chain is shorter, more transparent, and significantly more reliable.

Sourcing locally means you can avoid the long lead times and uncertainties associated with international freight. This drastically reduces the risk of costly disruptions and allows for more agile and responsive inventory management. You can get your products to market faster and adapt more quickly to changes in customer demand. This resilience is a powerful advantage in a fast-paced market, providing the stability you need to grow with confidence.

Seamless Communication and Collaboration

Effective communication is the cornerstone of any successful project, especially in complex manufacturing. When your manufacturing partner is in the same country, or even the same time zone, collaboration becomes seamless. There are no late-night calls to accommodate different business hours, and language barriers are non-existent. This leads to clearer communication, fewer misunderstandings, and a more efficient design and production process.

Proximity also allows for invaluable face-to-face interaction. The ability to visit the manufacturing facility, inspect prototypes firsthand, and work directly with the engineers and technicians on the shop floor is a significant benefit. This hands-on collaboration fosters a true partnership, allowing for rapid problem-solving and innovation. It ensures that your vision is executed precisely as intended, resulting in a better final product.

Protection of Intellectual Property

Your designs, innovations, and proprietary processes are among your company’s most valuable assets. Protecting your intellectual property is a major concern when outsourcing manufacturing, particularly to some overseas jurisdictions where IP laws may be less stringent or poorly enforced. The risk of your designs being copied or your trade secrets being compromised is a serious threat that can undermine your competitive advantage.

Working with a Canadian manufacturing partner offers robust legal protection for your intellectual property. Canada has a strong legal framework and a deep respect for IP rights, providing you with the peace of mind that your valuable designs are safe. This security allows you to innovate freely, knowing that your hard work and ingenuity will remain yours and yours alone.

Supporting the Local Economy and Building a Stronger Community

Choosing to manufacture in Canada has a positive ripple effect that extends far beyond your own business. It supports the national economy by creating and sustaining high-skilled jobs, from welders and machinists to engineers and project managers. This investment in local talent helps build a stronger, more prosperous community for everyone.

Furthermore, manufacturing locally reduces the environmental impact associated with long-distance transportation. A shorter supply chain means a smaller carbon footprint, which aligns with the growing consumer demand for sustainable and ethically produced goods. Highlighting your commitment to Canadian manufacturing can be a powerful part of your brand story, resonating with customers who value quality, sustainability, and community support.

At Waycon Manufacturing, we are proud to be a part of Canada’s vibrant manufacturing sector. We embody all the benefits of a local partnership, offering world-class expertise right here in British Columbia. Our commitment to quality, innovation, and customer collaboration is at the core of everything we do. We don’t just build parts; we build partnerships designed for long-term success.

Our team of experts leverages cutting-edge technology and years of hands-on experience to deliver exceptional results. We offer a comprehensive suite of services, from design and engineering support to custom fabrication and full-scale production runs. Our expertise in professional manufacturing ensures we can tackle projects of any complexity, delivering on time and on budget.

Discover the strategic advantage of partnering with a dedicated Canadian manufacturer. Let us show you how our local expertise and commitment to quality can help your business thrive.

Ready to strengthen your supply chain and elevate your products? Contact us today to discuss your manufacturing needs with our team of experts.