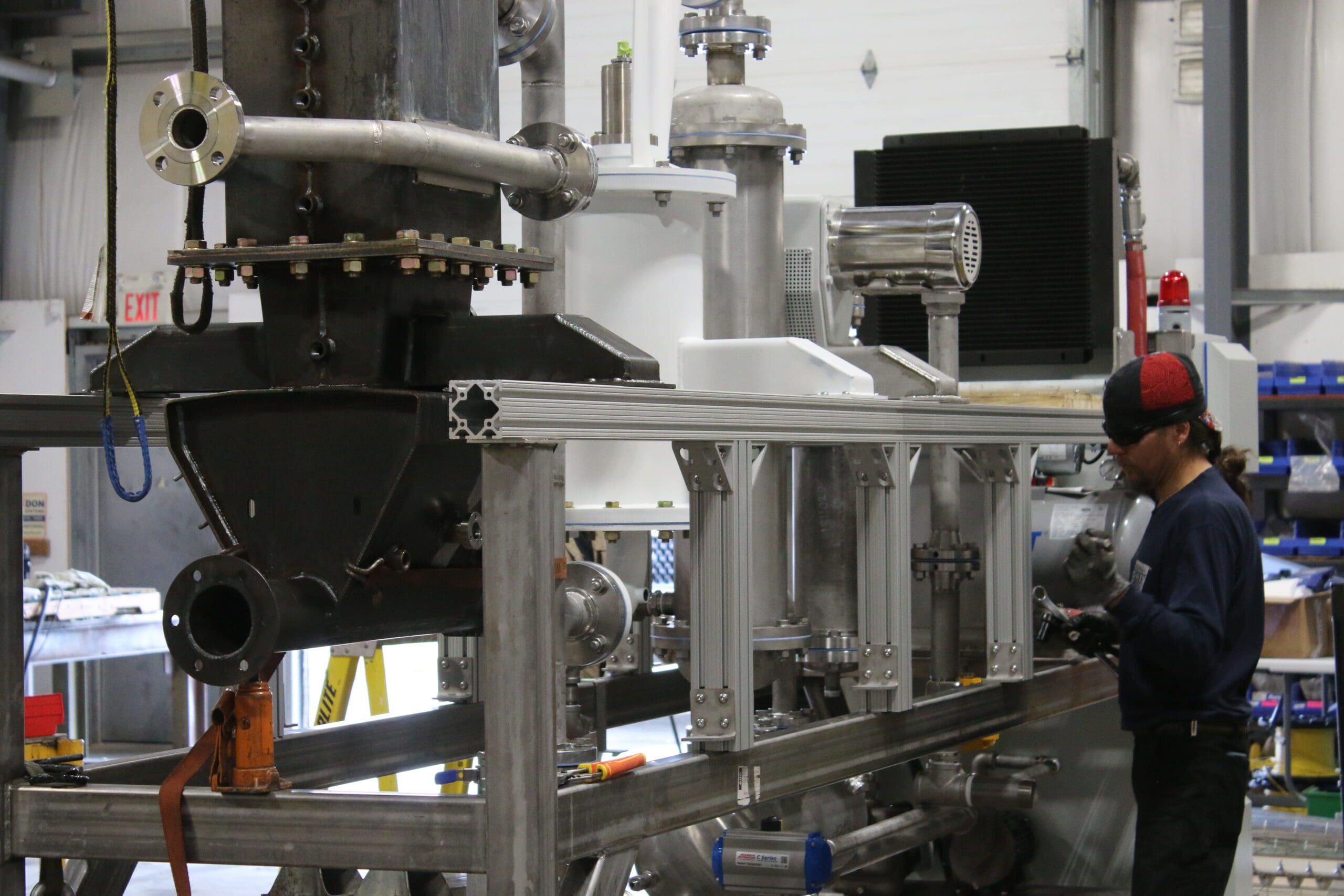

Since 1987, Waycon Manufacturing has been a trusted Canadian partner in OEM manufacturing and custom metal fabrication. Proudly Canadian-owned and operated, we specialize in delivering high-performance, Canadian-made solutions for industrial clients. Our turnkey approach includes engineering support, CNC machining, fabrication, finishing, and assembly—all handled in-house. This full-service model allows us to deliver seamless, start-to-finish manufacturing experiences for every project.

About Waycon Manufacturing

Backed by decades of experience and a state-of-the-art facility, we handle both small and large-scale projects with precision and efficiency. Whether you need high-tolerance components or complex fabricated assemblies, our scalable capabilities allow us to deliver results that meet rigorous industrial standards.

Beyond client-driven manufacturing, Waycon has a legacy of innovation. From our patented Fifth Wheel Slide to custom-built systems for fruit processing and excavator modifications, our engineered solutions are built to enhance safety, optimize performance, and improve production quality. Every system we create is the result of deep industry insight and a commitment to continuous improvement.

Company Milestones

“We Don’t Just Manufacture;

We Innovate.”

Our Core Values

Our founder’s mother inspired us with her strong work ethic, demonstrating the power of dedication and perseverance. Her commitment to providing for her family reminded us that success is earned through determination and diligence. She emphasized the importance of integrity and doing what is right, even when no one is watching. She taught us that honesty builds trust, the foundation of successful relationships with customers, employees, and partners.

These values of hard work and honesty are the guiding principles of our business. They shape our practices, reminding us that success is not solely determined by talent or luck, but by the combination of hard work, integrity, and unwavering commitment to our goals.

Our Vision

At Waycon, we aim to be a leader in precision manufacturing by setting new benchmarks in quality and innovation alongside pioneering the next era of manufacturing excellence.

Our Mission

At Waycon, our mission is to consistently deliver unparalleled craftsmanship and trailblazing solutions, fostering strong partnerships and enhancing industry standards.

Join the Waycon Family – Build the Career You Want

At Waycon Manufacturing in Penticton, BC, we offer more than just jobs—we offer lasting careers in custom fabrication and OEM manufacturing. As a Canadian-owned company, we’re proud to work on innovative projects that make an impact. Join a team where your skills are valued, your growth is supported, and your work shapes products built to perform.