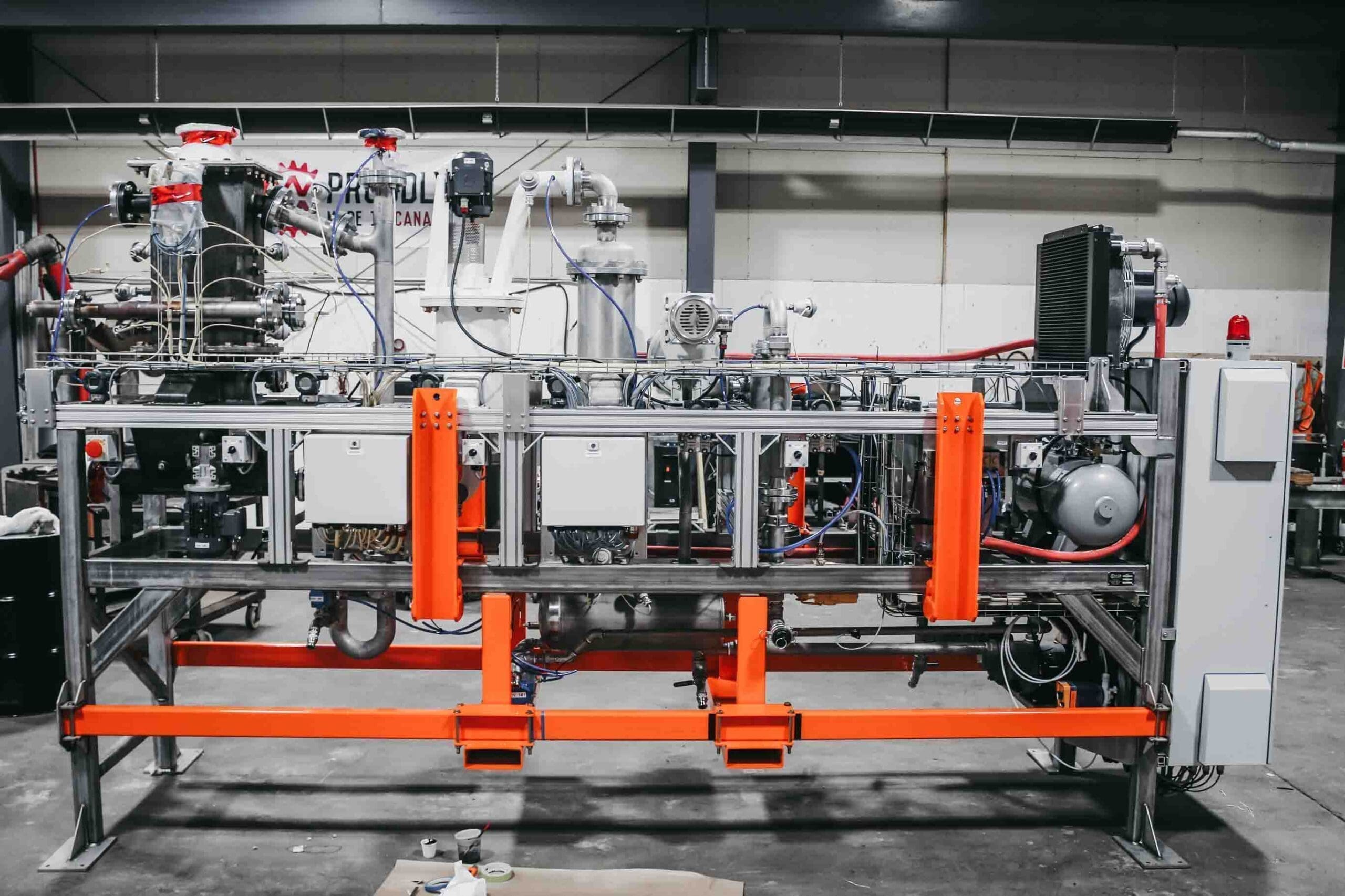

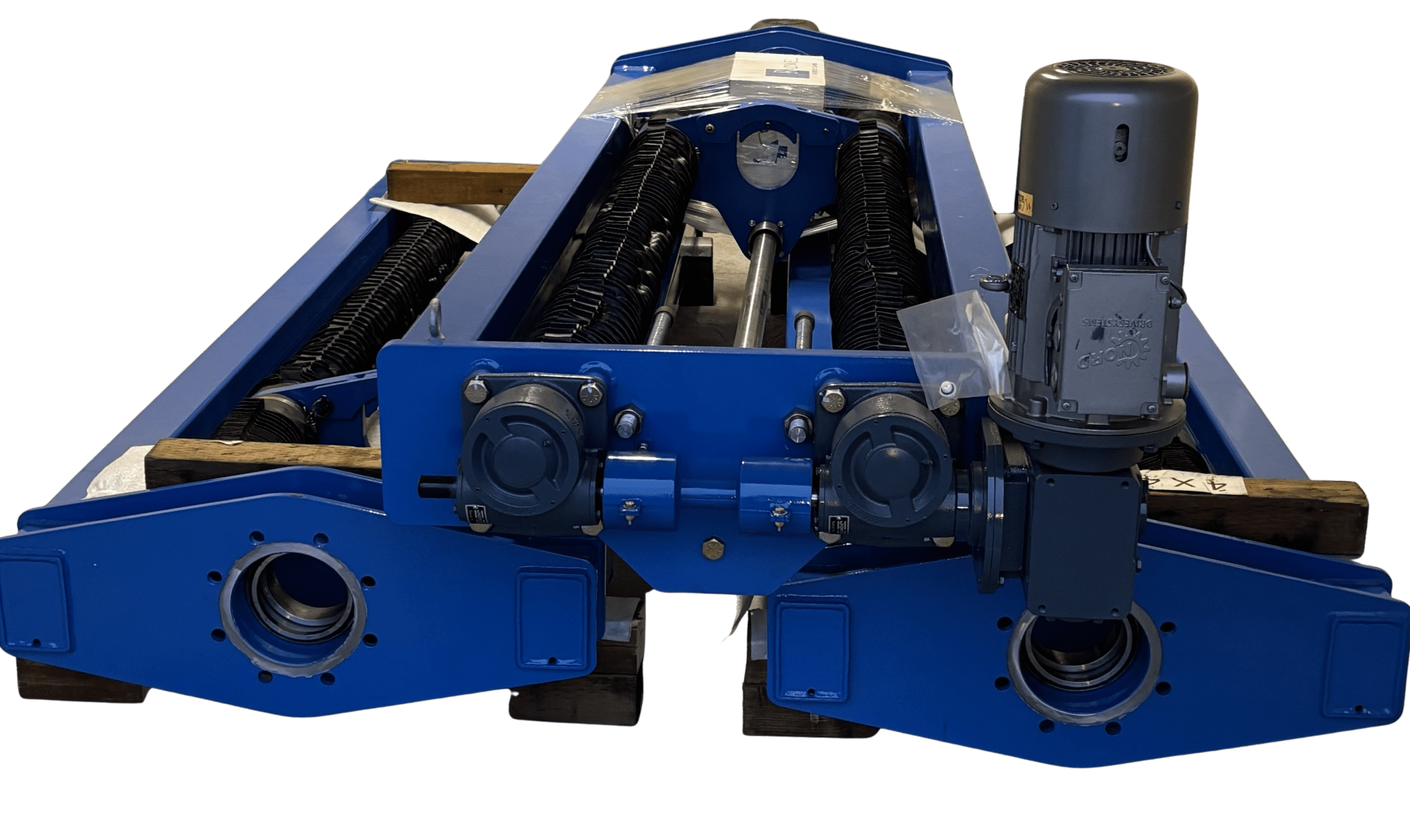

Waycon Manufacturing supports biomass energy and gasification projects by manufacturing build-to-print components, custom assemblies, and complete subsystems used in syngas production and energy conversion equipment. These projects require coordinated, system-level manufacturing where precision machining, fabrication, engineering, and assembly work together to support reliable operation in demanding industrial environments.

By delivering these capabilities in-house, Waycon helps streamline production, reduce handoffs, and maintain control from design through delivery.