With extensive manufacturing expertise and advanced equipment, we deliver build-to-print manufacturing solutions that meet the most exacting design requirements and specifications.

Your Trusted Build-to-Print Industrial Manufacturer

Build-to-print manufacturing brings your vision to life with precision and adherence to your exact specifications. From initial drawings to final assembly and testing, our skilled team ensures every step is flawlessly executed. Trust Waycon to deliver exceptional quality and craftsmanship tailored to your needs.

By partnering with us, you gain access to our extensive capabilities, including engineering support, diverse equipment, quality materials, and the expertise required for various manufacturing and assembly processes.

Discover how our team of experienced manufacturing engineers brings expertise and innovation to your project.

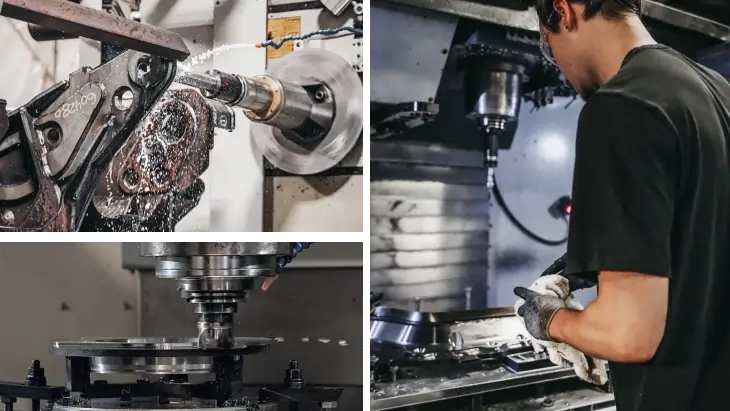

Using state-of-the-art CNC machining technology, we craft highly accurate components with tight tolerances. Our skilled machinists ensure every part meets the highest standards for quality, making them ideal for demanding industrial and commercial applications.

We provide expert welding and assembly services to deliver finished products that are both strong and functional. Our team of certified welders works with a wide variety of metals, ensuring seamless fabrication and reliable structural integrity for your components.

Utilizing advanced sheet metal cutting and forming techniques, we produce custom shapes and designs to match your exact specifications. Our commitment to precision ensures that every cut and bend results in a perfect fit for your project.

Our prototyping and design assistance services help you bring your ideas to reality. We work closely with you throughout the design phase to create functional prototypes, ensuring all aspects of your project are perfected before full production.

We offer a range of premium metal finishing options to enhance the appearance, durability, and functionality of your products. From powder coating to anodizing, our finishes are designed to meet the toughest industry standards while complementing your design.

Raymond Jodoin, Quanta Services

Waycon’s commitment to quality, reliability, and on-time delivery, along with their advanced engineering support and expertise in design for manufacturing, has played a key role in our success. We highly recommend Waycon as a reliable turnkey solution provider.

Our 40,000 sq. ft. facility on 2.2 acres is designed for heavy lifting and large CNC weldments. Our capabilities include:

- Engineering & Project Management

- CNC Cutting

- Precision CNC machining; Lathes, Mills, 4/5 Axis Boring Machines

- Forming & Bending

- Welding & Fabrication

- Heavy Lifting

- Sandblast & Paint

- Assembly

- Electrical, Automation, and Testing

Why Choose Waycon for Build-to-Print Services?

We offer integrated services that cover every aspect of your project from start to finish. Our team provides comprehensive engineering, advanced tooling, equipment, and specialized skills to ensure seamless project management and execution.

With a strong commitment to quality control, flexibility, and reliability, we ensure your projects are delivered on time and meet the highest standards. Our focus on punctuality and consistency guarantees the results you need, when you need them.

We specialize in tailoring solutions specifically for your industrial processes or challenges. Whether you require customized designs, unique features, or specialized systems, we provide solutions to fit your exact needs.

From design for manufacturability to advanced engineering support and prototyping, we offer top-tier engineering services to bring your ideas to life. Our team ensures that every design is optimized for performance, efficiency, and manufacturability.

Tell Us About Your Project

Do you need a custom machine? Email or call us, and our Project Engineer will connect with you to discuss your project.

Our Contact Details

Location 275 Waterloo Ave, Penticton BC V2A 7J3 Canada

Within our 40,000-square-foot manufacturing facility, our capabilities include CNC cutting, CNC machining, forming and bending, CWB welding, fabrication, sandblasting, painting, and assembly. Our state-of-the-art tooling enables us to hold tolerances of up to 0.0005 inches in diameter, and we can weld metals using processes such as metalcore, flux core, TIG, MIG, stick, hardwire, and full-pan welding. These specialized production capabilities enable us to manufacture to unique project requirements, ensuring we meet customer expectations for every product.

The cost of build-to-print manufacturing varies widely depending on several factors, including the complexity of the design, the materials used, and the production volume. For an accurate estimate, please contact us to discuss your project.

While the timeline of our build-to-print manufacturing process varies depending on the scope and complexity of the project, we are committed to meeting tight deadlines without modifying design specifications. Contact us to receive an estimate for your project.

There are several benefits of build-to-print manufacturing:

- Cost Efficiency: By outsourcing a build-to-print manufacturer, a business can avoid purchasing the equipment required to build the product.

- Flexibility: Build-to-print manufacturers are capable of scaling production volumes up or down depending on customer requirements and market demand.

- Consistent Quality: Partnering with a build-to-print manufacturer ensures quality remains consistent for every product.

- Expertise: Build-to-print manufacturers have the experience to manage all aspects of the production process efficiently, enabling businesses to significantly speed up their time to market and enhance their competitiveness.