Waycon Manufacturing provides advanced industrial manufacturing services to meet the diverse needs of modern industries. From precision components to complex assemblies, our team leverages decades of expertise and cutting-edge technology to deliver products that drive efficiency, reliability, and long-term performance in your operations.

Industrial Manufacturing

Comprehensive Solutions for Industrial Production

Trusted Leaders in Industrial Manufacturing

Since 1987, Waycon Manufacturing has been a trusted partner for industrial manufacturing solutions across Canada and the USA. Our commitment to precision engineering, innovative processes, and unmatched customer service has made us a preferred choice for industries like mining, automation, agriculture, and construction. With a focus on quality and dependability, we deliver solutions that consistently exceed expectations.

Our Production Capabilities

With expertise in engineering and manufacturing, we provide integrated services and project management from concept to commissioning.

We have 2 plasma tables 8 foot by 24 foot. Waterjet Cutting and Automatic Band Saw.

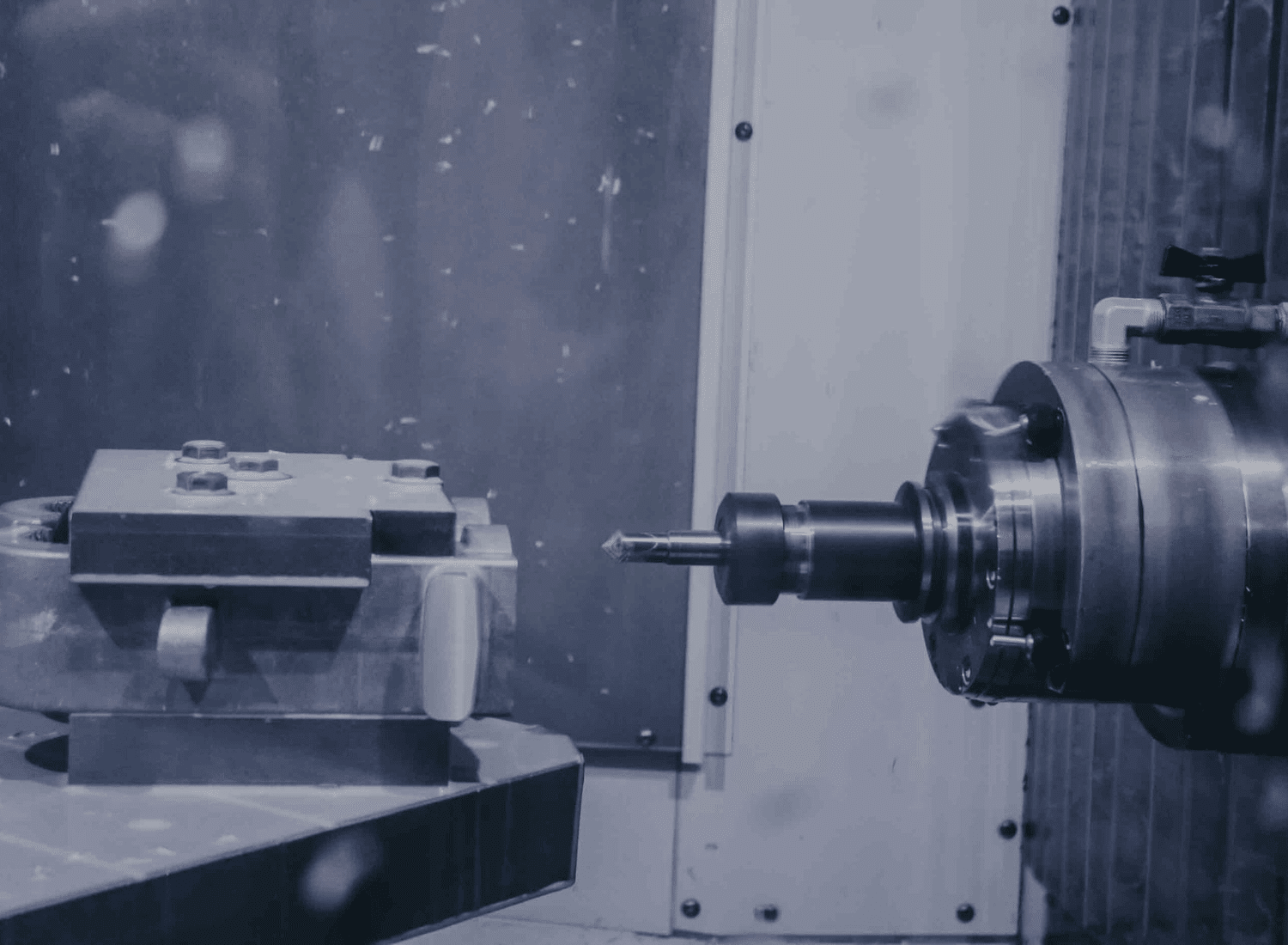

At Waycon, we have an extensive range of CNC machines horizontal boring, milling and lathes to handle a variety of projects. We use advanced CNC machining tools for precision component manufacturing.

We use Mastercam CAD/CAM software to create meticulous toolpaths and optimize cutting strategies, enabling us to provide exceptional parts.

We can bend and shape various materials to meet unique project specifications for industrial equipment manufacturing.

We are CWB-certified and have the expertise and equipment to fabricate your finished product precisely.

We have the equipment and expertise to hit tolerances within 0.0001 inches, ensuring every part meets the highest standards of quality and precision.

As a one-stop shop for industrial equipment manufacturing, we provide sandblasting and painting services.

We have the skills and technology to manufacture industrial projects with accuracy, ensuring every aspect of the assembly process is of the highest quality.

If commissioning is required, we perform a comprehensive final check to ensure each product is fully operational and meets all functional requirements.

Raymond Jodoin, Quanta Services

Waycon’s commitment to quality, reliability, and on-time delivery, along with their advanced engineering support and expertise in design for manufacturing, has played a key role in our success. We highly recommend Waycon as a reliable turnkey solution provider.

A Custom Manufacturing Process Tailored for Success

Strategic Planning

We begin with a client meeting to understand your project objectives and gather essential drawings and specifications, setting the foundation for success.

Innovative Prototyping & Design

Our mechanical engineers develop prototypes and preliminary designs, bringing your specifications to life while ensuring every detail aligns with your goals.

Collaboration

Throughout the entire process, we maintain open dialogue, offering recommendations, conducting design reviews, and refining drawings to meet your exact specifications.

Design For Manufacturability and Engineering Support

We meticulously produce production drawings, ensuring that every element is precisely engineered for optimal performance.

Strategic Procurement

Only the highest quality materials and parts are sourced from our established network of suppliers, ensuring we get the most competitive prices while guaranteeing durability and excellence.

Kick-Off Meeting

A kick-off meeting is conducted to align all teams, followed by the release of drawings to our skilled shop floor, ensuring a successful transition to manufacturing.

End-to-End Support

We provide continuous support during the manufacturing, finishing, assembly, and testing phases, ensuring that all manufacturing steps meet our high-quality standards.

Commissioning

The final product undergoes rigorous commissioning, ensuring it’s fully operational and ready to exceed your expectations.

Why Choose Waycon for Industrial Manufacturing?

End-to-End Solutions

We offer integrated services that cover every aspect of your project from start to finish. Our team provides comprehensive engineering, advanced tooling, equipment, and specialized skills to ensure seamless project management and execution.

Quality Assurance & Timely Deliveries

With a strong commitment to quality control, flexibility, and reliability, we ensure your projects are delivered on time and meet the highest standards. Our focus on punctuality and consistency guarantees the results you need, when you need them.

Custom & Tailored Solutions

We specialize in tailoring solutions specifically for your industrial processes or challenges. Whether you require customized designs, unique features, or specialized systems, we provide bespoke solutions to fit your exact needs.

Engineering & Design

From design for manufacturability to advanced engineering support and prototyping, we offer top-tier engineering services to bring your ideas to life. Our team ensures that every design is optimized for performance, efficiency, and manufacturability.

Do you need a custom machine? Email or call us, and our Project Engineer will connect with you to discuss your project.

Our Contact Details

Absolutely. Our facilities are equipped to manage both production runs and one-of-a-kind custom projects. We work closely with clients to ensure each solution is tailored to their needs and delivered on schedule.

Industrial manufacturing involves fabrication of components, parts, or systems for industrial use. It supports various industries whether mining, oil, gas, or renewable sectors by providing the equipment for efficiency, reliability, and safety in production processes.

Our offerings include engineering design, CNC Cutting, CNC machining, welding, fabrication, assembly, finishing, and rigorous quality testing. These end-to-end services ensure flexibility, timely deliveries, and quality results.

Absolutely. Our 40,000 sq. ft facility is equipped with the skill, tools, equipment, lifting capacity to manage contract manufacturing and one-of-a-kind custom projects. We work closely with clients to ensure each solution is tailored to their needs and delivered on time and within budget.

Getting started is easy. Give us a call 250-492-7718 or reach out through our contact page to discuss your project. Our team will guide you through the process, from initial design to final delivery, ensuring a smooth and efficient experience.