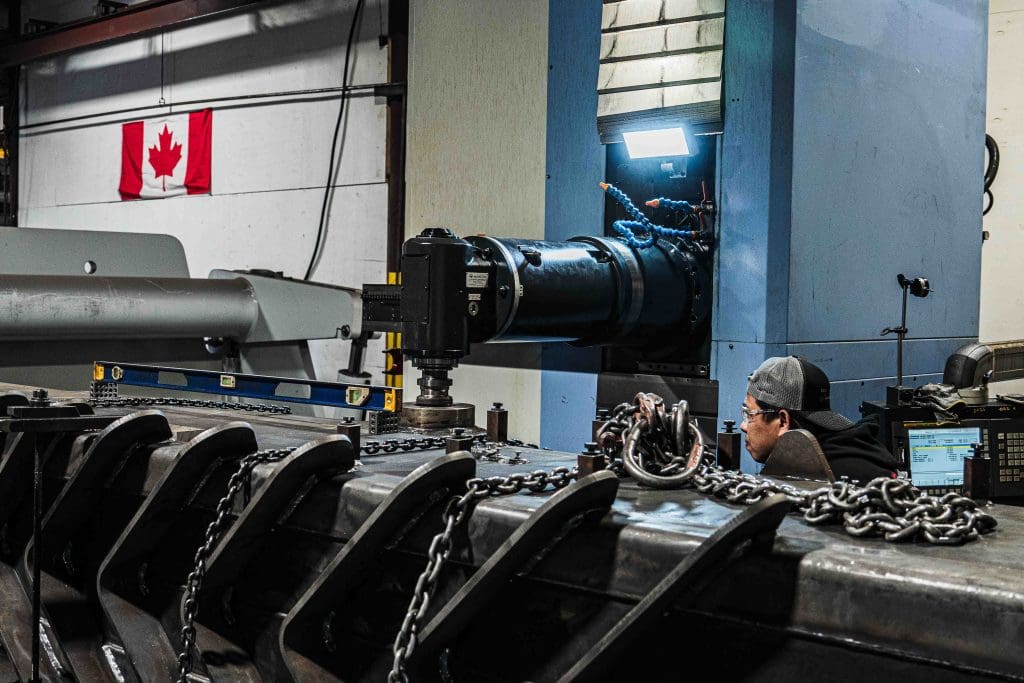

At Waycon Manufacturing, we provide large scale CNC machining services for heavy industries including mining, forestry and logging, agriculture, gasification, and energy.

Our 40,000 sq ft facility is equipped with advanced CNC machinery, including a Doosan Puma 5100LYB lathe and a DBC-110 horizontal boring mill. These capabilities allow us to machine and assemble components up to 20 ft in length and 22,000 lb in weight while maintaining tight, repeatable tolerances.