Hydrocooling is the process of rapidly cooling produce after harvest, in order to arrest natural respiration and maximize shelf life. This is achieved by circulating large volumes of near freezing water over the product in a controlled environment, generally integrated as a step in a larger process in a packing plant.

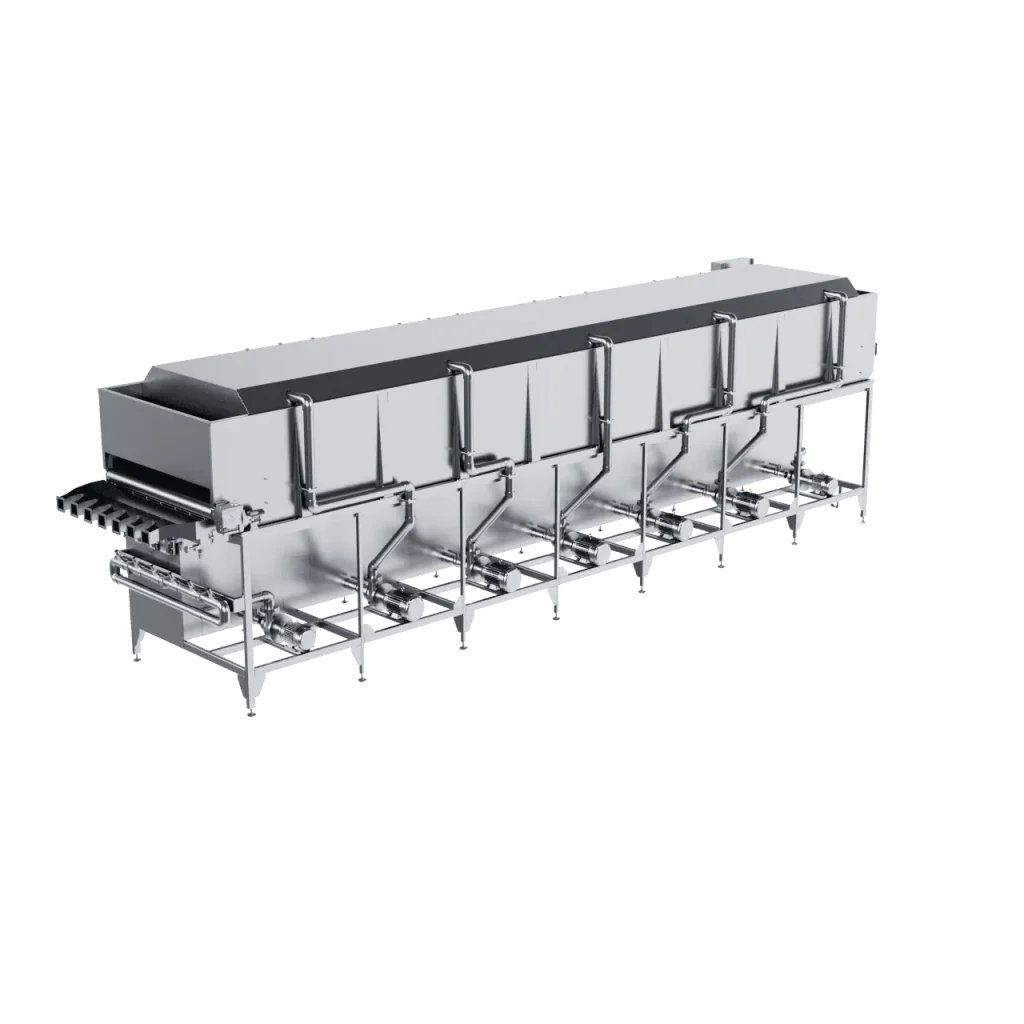

Hydro Cooling System

Description

Technical Specifications

- Standard models of inline cherry hydrocoolers ranging from 1.5 ton/hour to 15 ton/hour capacity in a single machine.

- Modular “Mini hydrocoolers” also available which can be ran in parallel to achieve desired throughput.

- Machines are of stainless-steel construction, with plastic modular conveyor belts.

- Copper direct expansion cooling coils with stainless steel distribution trays to ensure even flow. The refrigeration condenser will be located at the closest possible location on the exterior of the building

- High flow, full stainless construction water pumps.

- Clamshell roof design to allow clean-in-place of upper distribution trays.

- Removable in-line filter trays to keep process water clean for longer

- Insulated tank and upper structure with ACM exterior cladding

- Direct drive variable speed gearmotor

- Integrated water auto-fill and remote drain functions as required

FAQs

Our standard cherry hydrocoolers have a design fruit exit temperature of 35°F, based on a maximum incoming fruit temperature of 75°F.

The following are the standard single belt width hydrocoolers we manufacture

- 1.5 ton/hour

- 3 ton/ hour

- 6 ton/ hour

- 9 ton/ hour

- 12 ton/ hour

- 15 ton/ hour

- Our mini hydrocoolers have 2 x separated belts running side by side, with each belt having a capacity of 0.5 ton/hour.