Waycon’s In-Motion-Weigh conveyor was developed to accurately capture the weight of full totes of cherries as they were unloaded from bins and introduced onto the packing line. It has a smaller footprint than most comparable models on the market, while accurately capturing unit weight data at a high throughput.

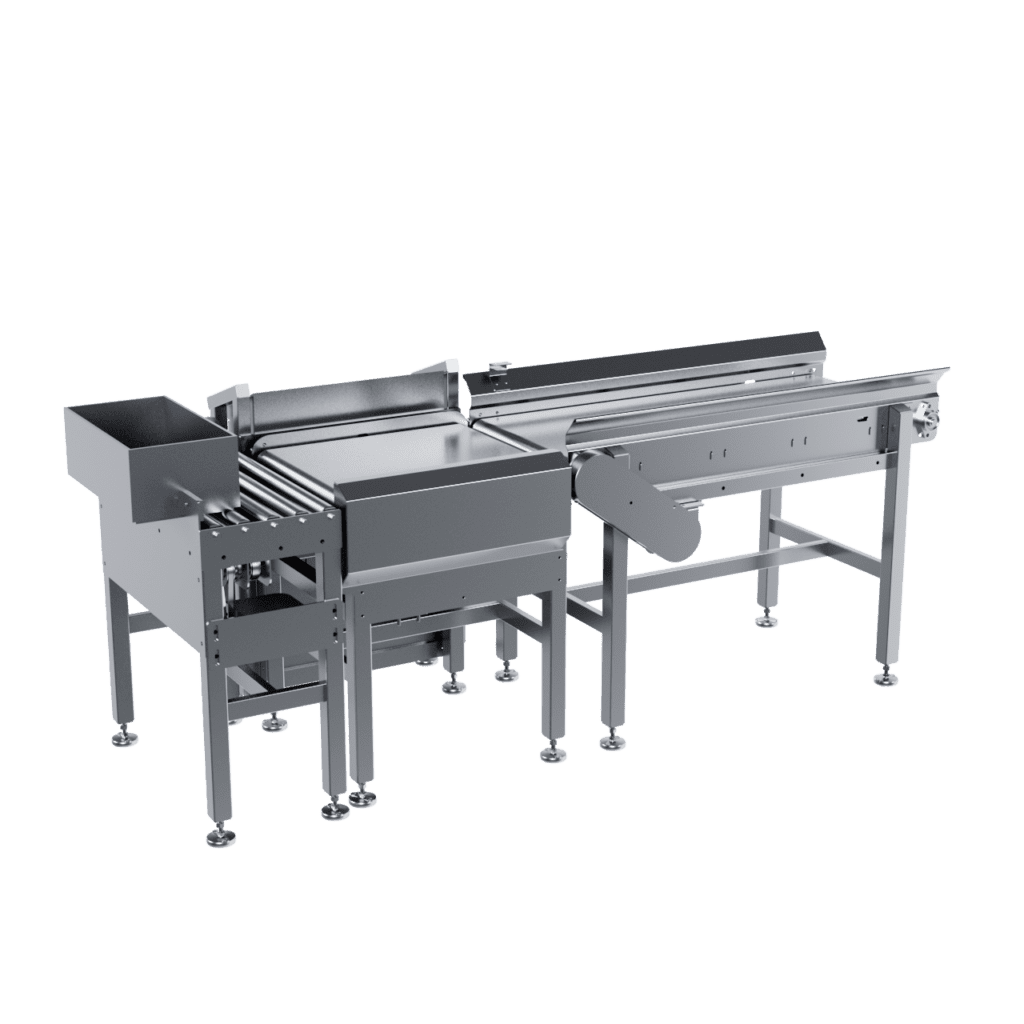

In-Motion Weigh Conveyor

Description

Technical Specifications

- Stainless-steel construction with plastic modular conveyor belt.

- Throughput capacity of up to 35 units per hour.

- +/- 0.5g accuracy.

- Adjustable speed, with 3 pre-set run speeds.

- Extremely small footprint, saving valuable floorspace

- Precision servo motor drives

- Integrated automation & controls, with intuitive color touchscreen interface

- Easy to calibrate and tare by the operator

- Integrated serial and ethernet date outputs to tie in with scanning and traceability systems.

FAQs

No, this product could be integrated into any system that requires in-motion weight capture of boxed product, i.e. weight check/reject system in a bottling or canning facility.