Biomass Gasification in Canada: Innovation, Growth & Waycon’s Role in Clean Energy

Biomass gasification — the thermal conversion of forest waste, municipal waste, or agricultural residue into syngas—is accelerating across Canada. As provinces push toward renewable natural gas (RNG), carbon reduction, and circular waste systems, gasification and pyrolysis technologies are moving from concept to commercial deployment. This ensures waste becomes fuel, carbon becomes a resource, and Canada builds energy security through home-grown clean power.

This article breaks down recent advancements in biomass gasification across Canada and how Waycon Manufacturing provides the precision fabrication required to build gasification systems, biochar equipment, and waste-to-energy plants at scale.

Why Biomass Gasification Matters for Canada’s Renewable Energy Future

Biomass gasification turns low-value waste into high-value energy.

Instead of landfilling, burning, or exporting biomass, gasification produces syngas, which can be converted into:

- Renewable natural gas (RNG)

- Electricity & industrial heat

- Renewable diesel, methanol, ethanol & SAF

- Biochar for long-term carbon sequestration

Canada generates millions of tonnes of biomass annually—especially in forestry-dense British Columbia & agricultural provinces. Converting even a fraction of this material into fuel would meaningfully support climate goals, rural economies, and energy independence.

- RNG production in Canada has grown 12x since 2010

- BC targets 15% RNG in natural gas supply by 2030

- 20+ waste-to-RNG projects expected to activate in 2025–2027

The market is scaling quickly — and needs manufacturers capable of building industrial gasification systems reliably and locally.

Where Gasification Is Advancing in Canada (2023–2029)

- Forestry Waste to Renewable Gas — British Columbia

REN Energy International is deploying gasification-to-RNG facilities that convert forest residue into pipeline-grade gas. By 2025, plants will supply 7.2 million GJ/year — about 25% of BC’s RNG target. - Municipal Waste to Biofuel — Edmonton & Quebec

Enerkem solidified Canada as an early global leader in waste gasification. Their Edmonton facility diverts 90% of municipal waste and produces methanol/ethanol for low-carbon fuels. A new Varennes, QC waste-to-methanol plant continues the model. - Wheat Straw to RNG — Prairies

Green Impact Partners is developing a facility that converts low-grade straw into RNG, proving agricultural feedstocks are now viable gasification streams. - Wood Waste to Liquid Fuels — Northern BC (BETL Process)

Expander Energy’s Mackenzie Biofuel Project will convert 84,000 tonnes/year of forestry waste into synthetic diesel & SAF using BETL—an advanced hybrid of gasification + electrolysis. - Biosolids to Biochar — Vancouver Island

The Capital Regional District approved Canada’s first wastewater gasification/pyrolysis system, producing biochar for permanent carbon storage.

➤ Every project above requires heavy fabrication, reactor vessels, material-handling systems, and engineered steel components — where Waycon is uniquely positioned to support.

The Benefits of Biomass Gasification & Pyrolysis

| Benefit | Description |

| Waste Reduction | Converts forestry waste, straw, biosolids & MSW into usable fuel — dramatically cutting landfill load. |

| Renewable Energy Production | Produces RNG, syngas, ethanol, renewable diesel, SAF & industrial heat. |

| Carbon Capture Through Biochar | Pyrolysis biochar locks carbon in a stable form for centuries. |

| Economic Growth & Jobs | Plants require manufacturing, construction & operational labor—creating jobs in clean tech. |

| Energy Security for Remote Communities | Gasifier CHP units reduce diesel reliance in northern & off-grid regions. |

Canada is now transitioning from pilot projects → commercial plants. To build them, the sector needs scalable manufacturing, reliability, and Canadian-made fabrication capacity.

Why Waycon Manufacturing Matters to the Gasification Industry

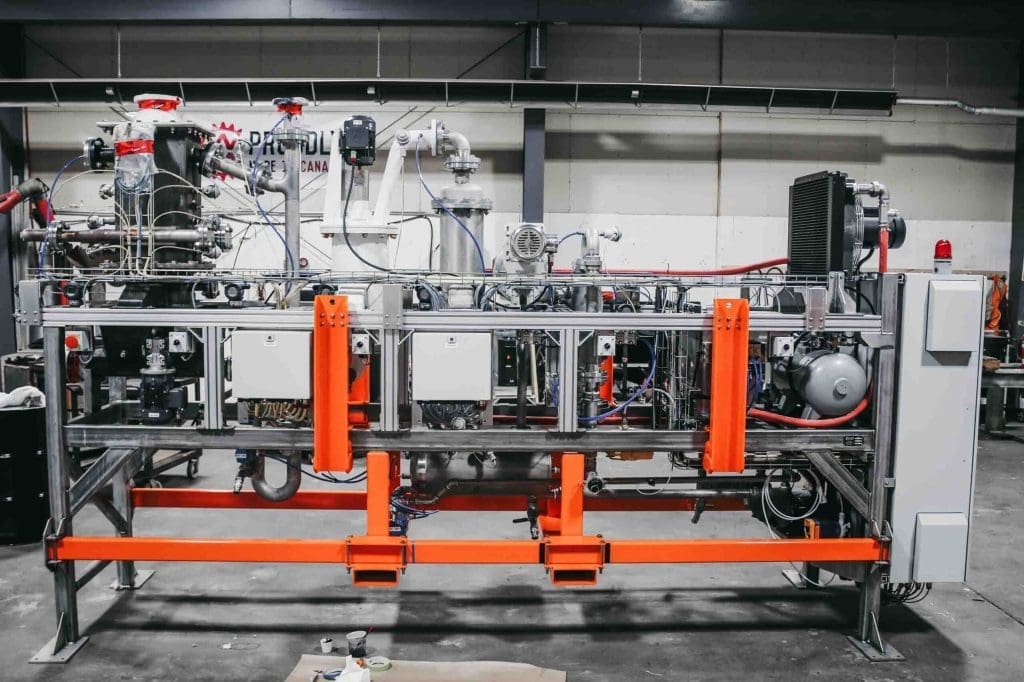

Waycon Manufacturing (Penticton, BC) provides turnkey fabrication for gasification systems, pyrolysis units, biochar reactors, and waste-to-energy equipment. Since 1987, we’ve supported Canada’s industrial & renewable technology sectors with high-precision, large-format manufacturing.

Waycon Capabilities for Biomass Gasification & Waste-to-Energy

| Capability | Relevance to Gasification Equipment |

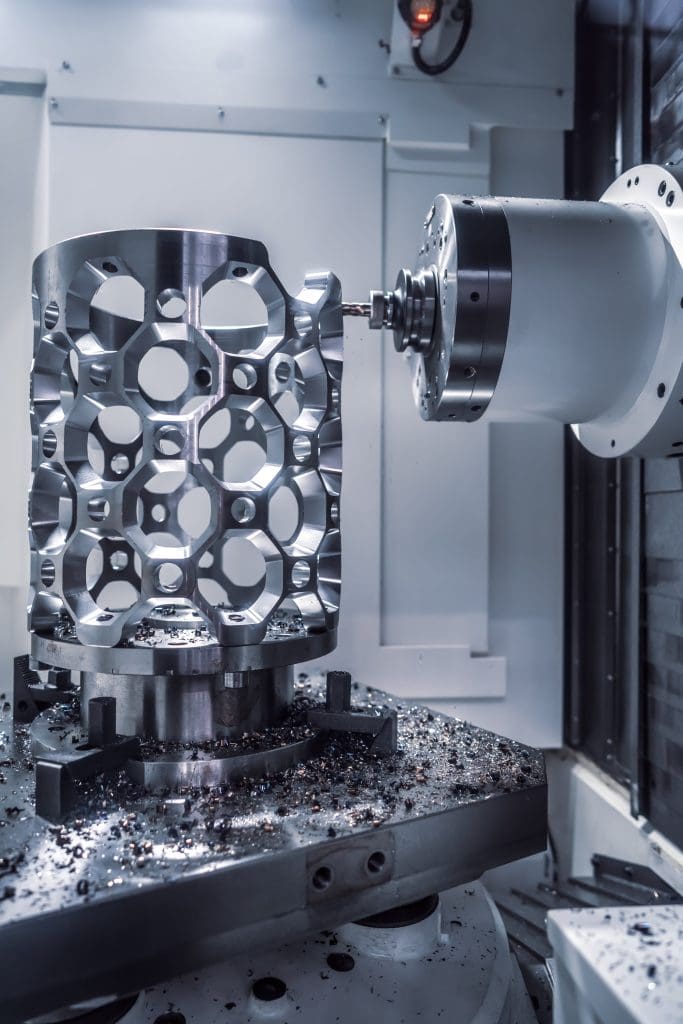

| CNC Machining to 22,000 lbs | Syngas reactors, flanges, burner assemblies, pressure components |

| 500-ton x 16′ Brake Press Forming | Heavy wall steel shells, ducting, cyclones, structural frames |

| CWB Welding Certification | Critical for pressure vessels & high-temperature assemblies |

| Full Turnkey Production | Design → fabrication → assembly → testing in-house |

| Custom Conveyance & Material-Handling Systems | Feed systems, discharge augers, hoppers, biomass pre-processing |

Waycon is designed for large, engineered systems requiring accuracy, durability, and supply-chain reliability.

With in-house engineering support, OEM partnership experience, and a 30+ year track record in industrial fabrication, Waycon bridges the gap between clean-tech design and commercial-scale deployment.

A Clean Energy Future — Built Here in Canada

Biomass gasification is no longer experimental — it is being implemented across forestry towns, agricultural regions, and municipal grids. As Canada scales this sector, the demand for high-quality domestic manufacturing will accelerate sharply.

Waycon stands ready to build the machinery that powers that shift.

From reactors to conveyors, frames to machined assemblies — if a project needs heavy steel, precision engineering, or full-system manufacturing, our team can deliver.

Let’s Build The Future of Clean Energy Together

If you’re developing:

🔹 a biomass gasifier system

🔹 a pyrolysis / biochar unit

🔹 an RNG or waste-to-fuel plant

🔹 industrial waste-processing equipment

Waycon can manufacture it — from prototype to scaled rollout.

📩 Contact us to discuss your project & request pricing packages.

Your next generation of gasification technology can be built right here in Canada.