Contract manufacturing companies play a critical role in today’s industrial landscape. They bridge the gap between vision and execution, helping Original Equipment Manufacturers (OEMs) and other industrial clients produce high-quality products efficiently. However, not all contract manufacturing companies are created equal. Industry leaders distinguish themselves by their superior capabilities, rigorous quality control, and ability to respond dynamically to market demands.

This blog dives into what sets top contract manufacturing companies apart and examines how Canadian-based Waycon Manufacturing is setting a high benchmark in the industry.

What Is Contract Manufacturing

Contract manufacturing is a collaborative process wherein companies outsource their production needs to specialized manufacturers. These partners handle end-to-end processes, from prototyping to full-scale production, allowing organizations to focus on innovation and market strategy.

The key to success lies in choosing a contract manufacturer capable of meeting your exact needs while ensuring consistency, quality, and cost-effectiveness.

How Top Contract Manufacturing Companies Excel

End-to-End Capabilities

Leading contract manufacturers are more than just production facilities. They provide comprehensive, end-to-end solutions that include everything from prototyping and engineering design to full-scale production and assembly. This saves clients time and hassle by reducing the need to coordinate multiple vendors.

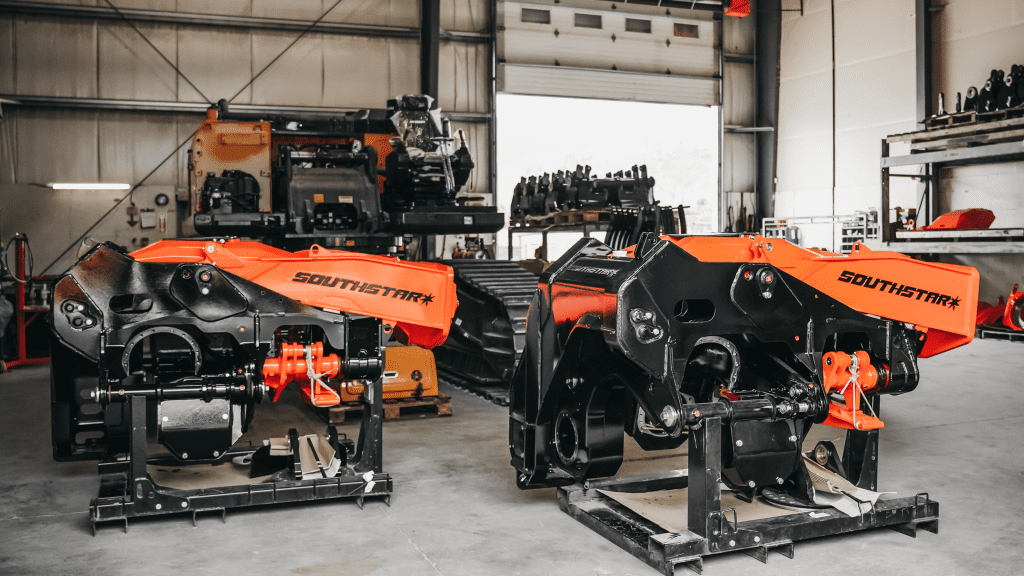

Waycon streamlines the manufacturing process by offering CNC machining, welding, forming, painting, and final product assembly under one roof. Whether it’s a complex prototype or a large production run, everything is completed in their state-of-the-art 40,000-square-foot facility in Penticton, BC.

Build-to-Print Expertise

Top manufacturers excel in “build-to-print” services, which involve executing complex designs provided by clients with high levels of precision and reliability. This is especially critical for sectors like mining, recycling, and industrial processing, where accuracy is paramount.

With years of proven expertise, Waycon has mastered build-to-print manufacturing, successfully executing projects for OEMs in diverse industries. Their attention to detail and precision ensures every product aligns perfectly with client specifications.

Certifications and Quality Assurance

Premium contract manufacturers adhere to stringent quality standards and implement robust inspection processes. These measures build trust and ensure consistency across long-term contracts.

Waycon is steadfast in its commitment to quality. They are CWB certified in CSA W47.1 and CSA W47.2 and employ rigorous quality control measures, material traceability, and cutting-edge technologies to meet the most stringent client requirements. This commitment builds trust with their industrial partners over the long term.

Flexibility and Scalability

Industry leaders are equipped to handle everything from low-volume prototypes to continuous production runs. This flexibility allows them to meet the evolving needs of their clients without sacrificing efficiency.

Waycon offers unmatched scalability in their operations. Whether you need a one-off prototype or a continuous production run, their infrastructure can adapt to meet your needs without compromising on quality.

Canadian-Based Production

There has been increasing pressure to bring manufacturing back to Canada due to global supply chain instability and rising freight costs. In fact, major contractors like General Motors are now being urged to relocate military production domestically, reinforcing the need for capable Canadian manufacturers (insauga).

Local production not only reduces lead times but also ensures compliance with national standards and supports domestic jobs. Proudly Canadian-owned and operated, Waycon provides a reliable, domestic alternative to overseas manufacturing. Their Penticton-based facility reduces lead times, eliminates logistical hurdles, and ensures accountability within every project.

Proven B2B Track Record

Leaders in contract manufacturing maintain strong reputations by consistently delivering for industrial clients, OEMs, and engineering teams on mission-critical projects. Their proven B2B experience becomes a key factor in building long-term partnerships.

With a broad client roster spanning mining, construction, recycling, and industrial processing, Waycon has established itself as a trusted partner for diverse industries. Their track record proves their ability to execute challenging projects with efficiency and precision.

Strategic Partnerships and Growing Demand

One of the defining trends in modern manufacturing is the rise of strategic partnerships, particularly in technology and industrial sectors. Companies increasingly seek manufacturers who not only produce products but also function as extensions of their own teams, offering strategic value.

Recent collaborations highlight this trend, such as the Cannabix Technologies agreement with Price Industries for manufacturing cutting-edge breathalyzers (thecanadianpressnews). Waycon’s ability to align with emerging industry needs positions them as an indispensable partner for businesses looking to innovate.

Why Waycon Manufacturing Stands Out

Waycon Manufacturing goes beyond traditional contract manufacturing by offering a client-first approach that incorporates flexibility, advanced technology, and comprehensive in-house capabilities. Their commitment to “concept-to-completion” services ensures every project is executed with precision and efficiency.

Core strengths of Waycon Manufacturing include:

- Complete Solutions: Full-service CNC machining, welding, equipment assembly, and quality assurance.

- State-of-the-Art Facility: Their Penticton factory is equipped with advanced tools and technology, including CAD software like SolidWorks and Mastercam.

- Customer-Centric Approach: A single point of contact ensures seamless communication throughout the project lifecycle.

- Industry Expertise: Their extensive portfolio spans sectors such as mining, automation, and energy, proving their ability to adapt and innovate across industries.

What the Future Holds

The push for reshoring manufacturing jobs and reducing reliance on unstable supply chains is becoming a national priority in Canada. Leading contract manufacturers like Waycon are well-positioned to lead this shift, offering the capabilities, expertise, and local accountability needed to meet evolving demands. For companies looking to stay competitive and maintain supply chain stability, choosing a reliable contract manufacturing partner is no longer optional. It’s essential.