Understanding CNC Machining in OEM Manufacturing

What is CNC Machining and How Does It Work?

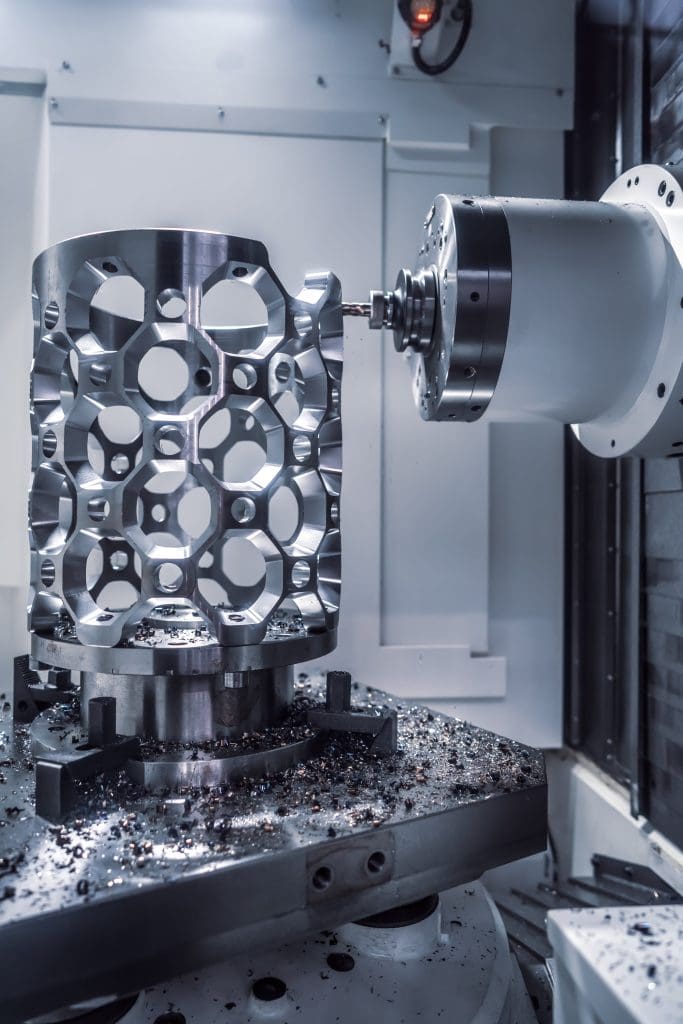

CNC (Computer Numerical Control) machining is a precision manufacturing process that uses computer-controlled tools to produce custom parts. For OEMs (Original Equipment Manufacturers), it allows for highly repeatable and accurate part creation, essential from early-stage prototyping through full-scale production.

Key aspects of how CNC machining works:

- CAM Software Integration: At Waycon, we utilize Mastercam CAM software to convert SolidWorks CAD designs into machine-readable instructions.

- Automated Cutting: CNC mills, lathes, and routers carry out precise cuts without manual intervention.

- Versatile Applications: Supports metals like aluminum, steel, and specialty alloys.

- Repeatable Accuracy: Parts can be reproduced to tolerances as tight as 0.0001”.

This precision makes CNC machining an essential solution within Waycon’s CNC machining capabilities, particularly for OEM engineers who need reliable results from prototype through production.

Why CNC is a Game-Changer for OEMs

CNC machining revolutionizes OEM manufacturing by streamlining workflows and reducing production risk. With computer-controlled accuracy and in-house fabrication, it offers:

- Rapid turnaround for prototypes and parts.

- Fewer errors compared to manual machining.

- Reduced costs by minimizing rework.

- Efficiency across product development cycles.

This is why Canadian OEM companies increasingly rely on CNC machining to meet tight tolerances, meet industry standards, and scale to volume.

Canadian Manufacturing Standards and CNC Practices

In Canada, CNC machining aligns with national certifications such as CSA, CWB, and ISO. Waycon adheres strictly to these, ensuring all projects meet regulatory and industry expectations.

- CWB-certified welders for structural components.

- CSA-compliant builds for electrical and mechanical systems.

- In-house QC protocols that exceed basic compliance.

Our focus on the Canadian manufacturing process ensures OEM clients receive consistent, audit-ready deliverables.

The OEM Workflow: From Prototype to Production

Design Phase: CAD Integration (SolidWorks)

Waycon starts every project by collaborating closely with OEM engineers to interpret or co-develop CAD models. Using SolidWorks:

- 3D visualization aligns team goals early.

- Interference detection is used to identify potential design issues.

- Integration with Mastercam allows direct transition to CNC programming.

Whether you’re designing from scratch or refining legacy components, our prototype services ensure that your vision is fully translated into manufacturable models.

CAM Programming with Mastercam for Precision

Mastercam allows us to generate detailed toolpaths directly from SolidWorks files. This software is key in ensuring that every part:

- Meets high-precision standards.

- Is machined in the most time-efficient way.

- Aligns with material capabilities.

Waycon’s experienced programmers use Mastercam to reduce manual input and increase machining speed, enabling shorter time-to-market for OEM customers.

Rapid Prototyping with In-House CNC Tools

Unlike shops that outsource early stages, Waycon offers in-house rapid prototyping using CNC tools. Benefits include:

- Quick turnarounds for urgent development cycles.

- Lower costs with no third-party markup.

- Direct feedback from machinists to engineers.

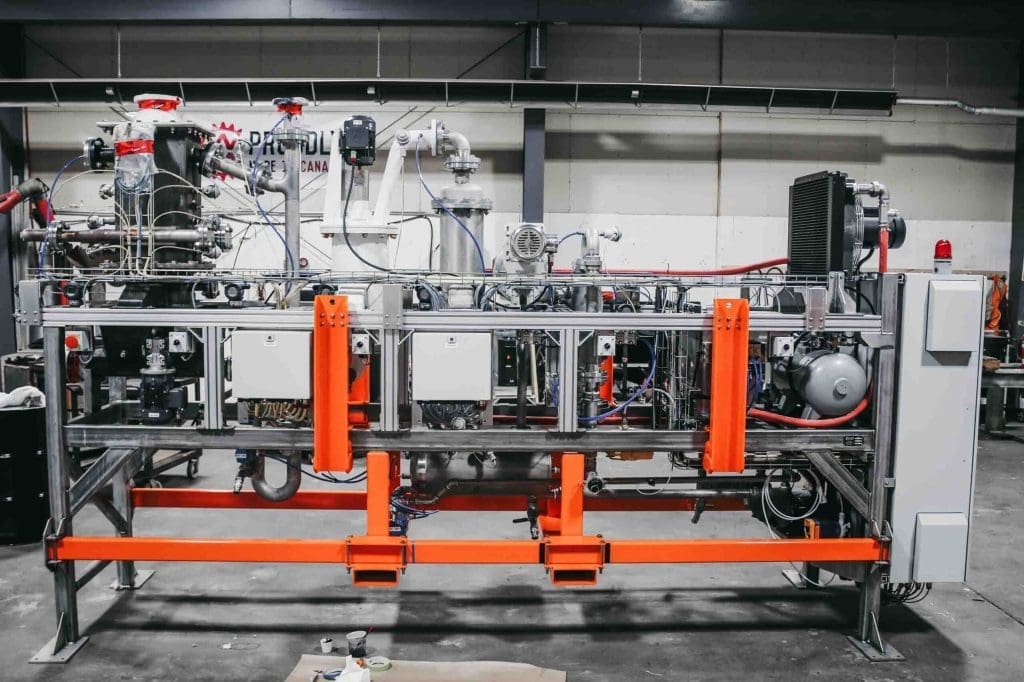

Our vertically integrated approach supports agile development and real-time improvements throughout the custom machinery manufacturing process.

Feedback Loops & Revisions

Waycon works iteratively with OEM clients. After each prototype iteration:

- Parts are evaluated for tolerance, fit, and function.

- Engineers receive feedback to update CAD designs.

- Final production methods are validated before full rollout.

This prototype-to-production approach reduces late-stage surprises, ensuring seamless scaling into production machining.

CNC Machining Benefits for OEM Production

Tolerances Up to 0.0001” – Why Accuracy Matters

Tight tolerances are critical in industries like aerospace, medical devices, and automation. CNC machining delivers precision through:

- Stable, calibrated equipment.

- Repeatable toolpaths created through Mastercam.

- In-house inspection systems including CMM and gauges.

For OEM engineers, this means consistent assembly fit and functional reliability across thousands of units.

Material Flexibility (Aluminum, Steel, Alloys)

Waycon machines a wide range of materials based on the needs of each OEM project:

- Aluminum: Lightweight and corrosion-resistant.

- Stainless Steel: For strength and hygiene-sensitive environments.

- Custom Alloys: Suitable for demanding thermal and mechanical conditions.

Our team guides OEMs through material selection to match performance and cost objectives.

Time Savings with In-House Tooling & Setup

Time is money in OEM production. With in-house capabilities, Waycon eliminates delays caused by third-party dependencies:

- Tooling and fixture development done on-site.

- Reduced downtime between prototype and production.

- Quick machine changeovers for smaller runs.

This agile process is especially beneficial for OEMs looking to streamline contract manufacturing under one roof.

Consistency Across Large Runs

OEM buyers depend on consistent part quality from unit 1 to 10,000. Waycon ensures this through:

- Run-to-run calibration checks.

- Automated toolpath simulation.

- Data tracking per part batch.

Consistency isn’t optional it’s engineered into every job.

Why Canadian OEMs Choose Local CNC Partners

Proximity & Communication Advantages

Being located in Penticton, BC, Waycon offers OEMs:

- Real-time communication in the same time zone.

- Faster logistics for shipping and site visits.

- Hands-on collaboration during design and testing.

These local advantages directly translate to fewer errors and improved project alignment.

Compliance with CSA, CWB, and Industry Standards

Waycon’s commitment to compliance is non-negotiable:

- CSA for electrical/mechanical compliance.

- CWB for welding and fabrication.

- ISO-style internal standards for QC processes.

For regulated industries, this gives peace of mind and reduces audit complexity.

Reduced Lead Times vs. Overseas Manufacturing

Working with a Canadian CNC partner like Waycon eliminates the typical pain points of offshore production:

- Shorter supply chains.

- No customs or import delays.

- Easier coordination on design changes.

Trust & Accountability in Contract Work

Waycon builds long-term relationships through:

- Transparent quoting and timelines.

- Direct access to machinists and project managers.

- Proactive communication during every phase.

This makes us a preferred choice for turnkey contract manufacturing in Canada where reliability and trust matter most.

Key Considerations for OEMs Choosing CNC Vendors

Technical Capabilities & Machinery

Waycon invests in advanced CNC machinery to handle complex OEM parts:

- 3- and 5-axis mills.

- High-speed turning centers.

- Multi-pallet systems for high-mix, low-volume jobs.

Our full equipment list is built for both prototyping and volume runs.

Quality Assurance and Inspection Protocols

OEM manufacturers rely on strict QA to meet specs and certifications. Waycon offers:

- First-article inspection for every project.

- In-process checks and final quality reports.

- Documentation per customer requirements.

Scalability from Prototype to Volume

Our infrastructure supports full-scale OEM workflows:

- Low-volume prototype runs with flexible setups.

- Mid- and high-volume production with dedicated lines.

- Seamless transitions between phases without vendor changes.

Waycon’s approach saves time and improves part continuity from one stage to the next.

Certifications (CWB, CSA, ISO if applicable)

Our certifications demonstrate a commitment to quality and safety:

- CWB-certified welding team.

- CSA-standard compliance in equipment builds.

- ISO-style documentation for traceability.

OEM engineers can trust that Waycon’s work meets global manufacturing standards.

The Future of CNC in OEM Manufacturing

Automation, AI Toolpaths, and Smart Machining

CNC technology continues to evolve with automation and AI-driven innovations:

- Smart toolpath optimization using Mastercam’s AI features.

- Automated part loading and inspection.

- Reduced human error through predictive analytics.

These advances are helping OEMs unlock next-level productivity.

Digital Twins & Simulated Manufacturing

Digital twins allow Waycon to simulate machining before cutting begins. Benefits include:

- Fewer prototype cycles.

- Toolpath efficiency.

- Design validation without material waste.

It’s a digital-first approach that modern OEMs appreciate.

Sustainability in CNC Processes

Sustainability is part of smart manufacturing. Waycon focuses on:

- Material efficiency and low-waste processes.

- Recycling metal chips and scrap.

- Energy-efficient equipment.

Canadian OEMs committed to sustainability will find strong alignment in our approach.

Conclusion: Why CNC is the Backbone of OEM Manufacturing in Canada

Summary of Key Benefits

Waycon’s CNC services support every stage of OEM manufacturing by:

- Reducing time-to-market.

- Improving part precision.

- Offering turnkey, local support.

- Delivering compliance-ready results.

Our CNC machining services are optimized for Canadian OEMs seeking competitive advantage.

How to Start a Prototype-to-Production Project

Getting started is simple:

- Send your CAD files for review.

- Work with our team to define specs.

- Receive a detailed quote and timeline.

- Begin prototyping, testing, and scaling.

Our custom prototype machining services make the transition to production smooth and efficient.

Contact Waycon for Custom OEM CNC Services

Ready to bring your OEM concept to life? Visit our custom machinery manufacturing page or contact us directly to begin your prototype-to-production journey.

Partner with a Canadian CNC shop that delivers accuracy, speed, and trust partner with Waycon.