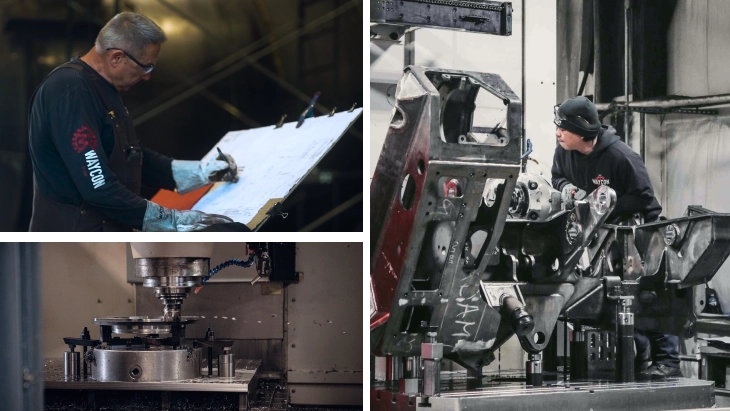

With deep expertise in manufacturing engineering, Waycon delivers industry-leading design and production solutions through fully integrated services. Using advanced tools like SolidWorks, our team ensures precision at every stage of your project. Our engineering and manufacturing teams work closely together to provide a seamless, collaborative approach from concept to completion.

Manufacturing Engineering Services

Professional Metal Manufacturing & Engineering

Your Trusted Engineering Manufacturing Company

From concept to commissioning, our engineering team and manufacturing operations work closely with you to create engineering manufacturing solutions that align with your specific industrial requirements.

With this integrated approach, our mechanical engineers have extensive knowledge and hands-on experience in all aspects of product development and industrial manufacturing, ensuring our customers receive high-quality products.

Discover how our team of experienced manufacturing engineers brings expertise and innovation to your project.

We offer engineering manufacturing for heavy-duty machinery, including forestry cabs, excavator conversions, excavators, undercarriages, and decks.

In addition to assisting our customers with engineering manufacturing for big machinery, we also specialize in creating custom parts and attachments such as harvesting processing heads, grapples, booms, and sticks.

We offer manufacturing engineering services for various industrial systems, such as hydro cooling systems, silos, conveyors, and fruit processing equipment, as well as for process systems, including product conveyor systems and integrated hydraulic systems.

Our team is well-versed in heavy equipment design for a range of industries. We have knowledge of manufacturing engineering for various pieces, including in-motion weigh conveyors and bin dumpers.

Our team of engineering manufacturing experts can produce various forms of mechanical automation, including robotic arms, advanced conveyor systems, and sophisticated automation tools.

Raymond Jodoin, Quanta Services

Waycon’s commitment to quality, reliability, and on-time delivery, along with their advanced engineering support and expertise in design for manufacturing, has played a key role in our success. We highly recommend Waycon as a reliable turnkey solution provider.

Our 40,000 sq. ft. facility on 2.2 acres is designed for heavy lifting and large CNC weldments. Our capabilities include:

- Engineering & Project Management

- CNC Cutting

- Precision CNC machining; Lathes, Mills, 4/5 Axis Boring Machines

- Forming & Bending

- Welding & Fabrication

- Heavy Lifting

- Sandblast & Paint

- Assembly

- Electrical, Automation, and Testing

Why Choose Waycon for Manufacturing Engineering Services?

We offer integrated services that cover every aspect of your project from start to finish. Our team provides comprehensive engineering, advanced tooling, equipment, and specialized skills to ensure seamless project management and execution.

With a strong commitment to quality control, flexibility, and reliability, we ensure your projects are delivered on time and meet the highest standards. Our focus on punctuality and consistency guarantees the results you need, when you need them.

We specialize in tailoring solutions specifically for your industrial processes or challenges. Whether you require customized designs, unique features, or specialized systems, we provide solutions to fit your exact needs.

From design for manufacturability to advanced engineering support and prototyping, we offer top-tier engineering services to bring your ideas to life. Our team ensures that every design is optimized for performance, efficiency, and manufacturability.

Tell Us About Your Project

Do you need a custom machine? Email or call us, and our Project Engineer will connect with you to discuss your project.

Our Contact Details

Location 275 Waterloo Ave, Penticton BC V2A 7J3 Canada

At Waycon, our services include engineering support, design for manufacturability, and prototyping. With this diversified skillset, our customers receive tailored services for their unique requirements.

We have experience working with engineering firms, OEMs, and businesses in agriculture, construction, government, mining, forestry, sawmills, energy, and transportation. Get in touch with us to discuss your project.

We use advanced Mastercam CAD/CAM and/or SolidWorks software for all of our projects. This program allows us to provide quality results for our customers and ensures precision in design and production.

The timeline for engineering manufacturing depends upon your specific project’s scope and complexity. Contact us to receive an estimate tailored to your project.

The cost of our engineering manufacturing services varies widely depending on several factors. These factors include the complexity of the project, the level of engineering support required, the materials used, the scope, and whether any specialized processes are involved. Contact us to receive a quote for your project.