Engineering & Production

The engineering department utilizes cutting-edge technology and industry standards for designing top-quality mechanical components and systems, employing SolidWorks 3D CAD and integrated software for optimal accuracy and productivity. Production meticulously plans and schedules activities to maximize resource efficiency. Through close monitoring and inter-departmental coordination, we ensure timely delivery.

Stainless Steel

Our dedicated stainless-steel department is home to a team of experts in stainless steel and aluminum weld and fabrication. With a strong focus on GTAW/TIG we have honed our skills to deliver exceptional results in a wide range of projects. From agricultural and food processing equipment to specialty stainless steel or aluminum projects. Anything stainless/aluminum related happens here.

CNC Cutting

Our advanced CNC cutting department utilizes state-of-the-art machines to precisely cut various materials, ensuring accuracy and efficiency in fabrication to meet customer specifications. We handle diverse steel grades like 44W, 80W, Qt100, AR 400, AR 500, Stainless Steel, and Aluminum, catering to different levels of strength and abrasion resistance. Our experienced team adeptly works with these materials for applications ranging from heavy machinery to wear-resistant equipment, providing reliable and durable solutions.

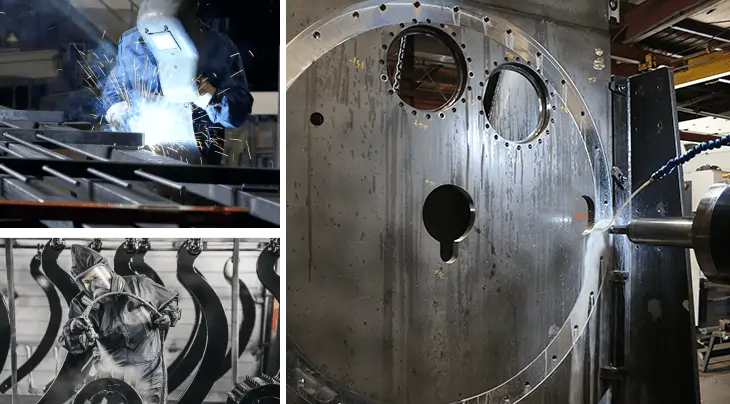

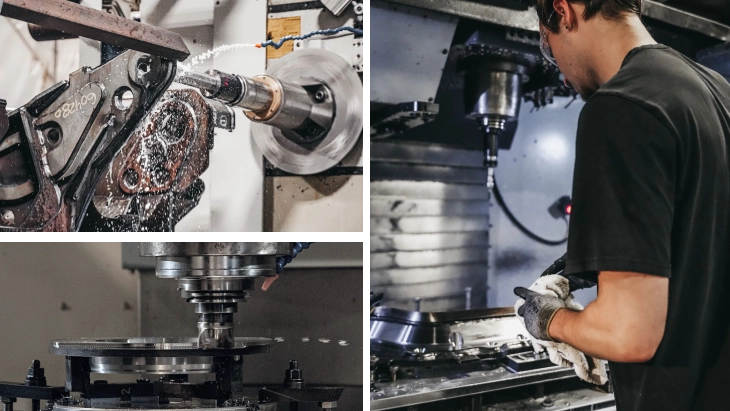

CNC Machining

Our CNC Machining division boasts a variety of advanced machinery, including lathes, mills, and horizontal boring machines, operated by skilled red seal machinists. We specialize in manufacturing complex parts of any size with high precision, using quality tools and industry-leading Mastercam software for detailed execution. Our state-of-the-art CNC equipment enables us to achieve tight tolerances up to +/- .0005", ensuring each part meets our clients' exact specifications and requirements.

Brake Press

Our advanced brake press equipment offers extensive forming capabilities, operated by experienced operators skilled in quick setup and precision part delivery, and they are proficient in programming and understand various forming and bending techniques. We can handle materials up to 3 inches thick and 16 feet long, accommodating a diverse range of projects from small components to larger structures. Equipped with a crane, our capabilities range from 170 to 500 tonnes, enabling us to manage projects of varying sizes and complexities with ease.

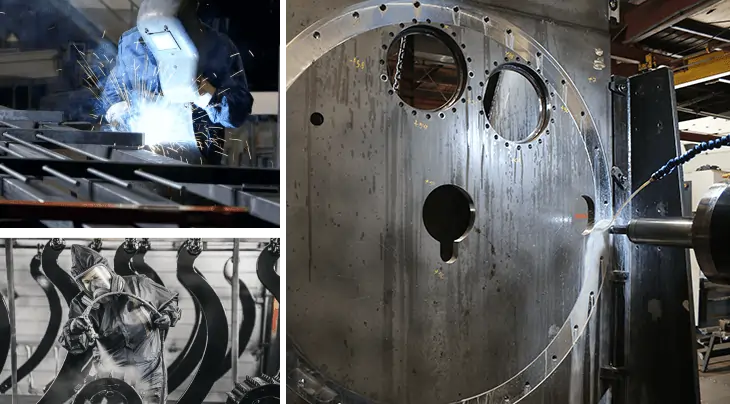

Welding & Fabrication

Our welding department team is proficient in various welding processes including flux core, metal core, MIG, TIG, stick, hardwire, and full pen welding. We maintain certifications from the Canadian Standards Association (CSA) and the American Welding Society (AWS) to ensure quality in all our welding processes. Adhering to standards like CSA W47.1 and W47.2 for steel and aluminum welding, along with AWS D1.1 and D1.2, we have dedicated machines for each process. At Waycon, our combination of certifications, skilled team, and advanced equipment allows us to handle welding projects with precision and efficiency, whether it's structural steel, aluminum, or any other material.

Paint & Sandblast

We utilize high-quality ENDURA paint to ensure a durable and long-lasting finish on all projects. Our facility is equipped with large bay doors, allowing for easy access to the main paint area measuring 30 ft x 25 ft. Additionally, we have a dedicated prep area measuring 25 ft x 25 ft to ensure thorough and precise surface preparation. With our state-of-the-art setup and commitment to excellence, we guarantee exceptional results for all your industrial painting needs.

Assembly / Shipping

Our assembly department is the final stage of production, ensuring that your products are completed and ready for shipment. Equipped with a 5-ton crane, our assembly department specializes in mechanical, electrical, and plumbing assembly, allowing us to handle diverse projects with precision and efficiency. Whether it's assembling Waycon cabs, excavator conversions, or processing heads, we have the expertise and resources to tackle any assembly challenge.